Understanding Water Hammer Arrestors: Causes, Effects, and Solutions

Understanding Water Hammer Arrestors: Causes, Effects, and Solutions

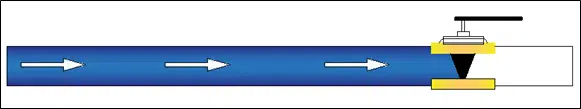

Water hammer is a common plumbing issue that can cause loud banging noises, vibrations, and even potential damage to pipes and appliances. It occurs when the flow of water in a pipeline is suddenly stopped, creating a pressure surge that reverberates through the system. The solution to this issue lies in the use of water hammer arrestors, which are designed to absorb the shockwaves caused by sudden water stoppages and protect your plumbing infrastructure.

What is Water Hammer?

Water hammer occurs when moving water is suddenly forced to stop or change direction, usually due to the quick closure of valves or faucets. The momentum of the water causes a pressure spike, which can damage pipes, valves, and other connected appliances. The effects include:

- Loud banging noises

- Vibrations in pipes

- Potential for pipe bursts or leaks

How Does a Water Hammer Arrestor Work?

A water hammer arrestor functions like a shock absorber in a car. It uses a sealed chamber filled with air or gas and a piston to cushion the pressure wave when water suddenly stops flowing. This prevents the pressure spike from causing damage or creating noise.

In detailed terms, as the pressure surge from water hammer hits the arrestor, the piston inside compresses the air chamber, dissipating the energy from the shockwave. After the surge has passed, the piston returns to its original position, ready for the next event. This technology is highly effective at mitigating water hammer, whether in residential or commercial settings.

Types of Arrestors:

- Mechanical Piston Arrestors: Utilize a piston to separate the air cushion from the water, preventing air absorption and maintaining effectiveness over time.

- Hydraulic Shock Arrestors: Use a flexible diaphragm or bladder to absorb the shock, suitable for various pressure ranges.

- Air Chambers: Simple vertical pipes that trap air; however, they can become waterlogged and lose efficiency without regular maintenance.

Benefits of Using Water Hammer Arrestors

- Noise Reduction: Eliminates the banging and thumping sounds associated with water hammer, creating a more peaceful environment.

- Protection of Plumbing System: Prevents damage to pipes, joints, valves, and connected appliances, reducing the risk of leaks and costly repairs.

- Extended System Lifespan: By minimizing stress on the plumbing infrastructure, arrestors contribute to longer-lasting pipes and fixtures.

- Compliance with Codes: Many building codes and standards require the installation of water hammer arrestors in certain situations, ensuring legal compliance.

Types of Water Hammer Arrestors

Residential vs. Commercial Arrestors

- Residential Arrestors:

- Designed for household plumbing systems.

- Typically smaller and suitable for individual fixtures like faucets, washing machines, and dishwashers.

- Commercial Arrestors:

- Built for larger systems with higher flow rates and pressures.

- Used in buildings such as hotels, hospitals, and industrial facilities where water hammer effects can be more severe.

Size and Capacity Considerations

Sizing Factors:

- Pipe Size and Length: Larger and longer pipes may require bigger arrestors.

- Water Pressure and Flow Rate: Higher pressures and flow rates demand arrestors with greater shock absorption capacity.

- Fixture Type and Frequency of Use: Fixtures that operate frequently or have quick-closing valves need appropriately sized arrestors.

Arrestor Sizing Charts:

Manufacturers provide sizing charts and guidelines to help select the correct arrestor based on the specific requirements of your plumbing system. Correct sizing is crucial for optimal performance.

Materials and Construction

- Common Materials:

- Brass: Durable and corrosion-resistant, suitable for most residential applications.

- Stainless Steel: Offers superior corrosion resistance, ideal for commercial or industrial settings.

- Copper: Common in residential systems, providing good durability.

- Corrosion Resistance:

- Selecting materials compatible with the type of water (e.g., hard, soft, or chemically treated) prevents premature degradation.

Installation of Water Hammer Arrestors

Identifying Installation Points

Critical Locations:

- Near appliances with quick-closing valves, such as washing machines and dishwashers.

- At the end of long pipe runs where water momentum is greater.

- Close to fixtures that are causing noticeable water hammer issues.

System Assessment:

Conduct a thorough inspection or consult a professional plumber to identify the areas where water hammer is most problematic.

Installation Guidelines

Professional vs. DIY Installation:

- Professional Installation: Recommended for ensuring compliance with local codes and proper functionality.

- DIY Installation: Possible for those with plumbing experience, but caution and adherence to guidelines are essential.

Step-by-Step Installation:

- Shut Off Water Supply: Turn off the main water valve to prevent flooding.

- Drain the System: Open faucets to relieve pressure and drain excess water.

- Access Pipework: Locate the installation point and expose the pipes.

- Install Arrestor:

- Use appropriate fittings (threaded, soldered, or push-fit).

- Ensure correct orientation as per manufacturer’s instructions.

- Restore Water Supply: Turn the water back on slowly, checking for leaks.

- Test the System: Operate the fixtures to confirm that the water hammer issue has been resolved.

Tools and Equipment Needed:

- Pipe cutter or hacksaw

- Wrenches

- Soldering equipment (if necessary)

- Teflon tape or pipe joint compound

- Safety equipment (gloves, goggles)

Compliance with Plumbing Codes

Local Regulations:

- Check with local building authorities to understand any specific requirements.

- Permits may be required for certain installations.

Standards and Certifications:

- Choose arrestors certified by recognized organizations, such as the American Society of Sanitary Engineering (ASSE) Standard 1010, to ensure quality and compliance.

Maintenance and Troubleshooting

Regular Inspection

Visual Checks:

- Inspect arrestors periodically for signs of corrosion, leaks, or physical damage.

- Ensure that pipe supports and fittings remain secure.

Performance Monitoring:

- Listen for any return of banging noises.

- Monitor water pressure and flow rates for anomalies.

Common Issues and Solutions

- Arrestor Failure:

- Causes: Wear and tear, sediment buildup, or faulty components.

- Solution: Replace the arrestor with a new, properly sized unit.

- Persistent Water Hammer:

- Causes: Incorrect sizing, improper installation, or additional underlying issues.

- Solution: Re-evaluate the system, consider installing additional arrestors, or consult a professional plumber.

Replacement Guidelines

Lifespan of Arrestors:

- Quality arrestors can last many years but may require replacement if they fail or if plumbing modifications are made.

Signs Replacement is Needed:

- Return of water hammer noises.

- Visible signs of wear, corrosion, or damage.

- Decreased effectiveness in absorbing shocks.

Disposal and Environmental Considerations:

- Dispose of old arrestors according to local regulations, recycling materials when possible.

Alternative Solutions to Water Hammer

Air Chambers

- Description: Vertical sections of pipe that trap air to absorb shock.

- Limitations: Over time, air can dissolve into the water, rendering the chamber ineffective.

- Maintenance: Regular draining may be required to replenish the air cushion.

Pressure Reducing Valves

- Function: Reduce the incoming water pressure to a manageable level.

- Benefits: Lower pressure can decrease the severity of water hammer and improve overall system efficiency.

- Installation Considerations: May be installed at the main water supply entry point.

Pipe Support and Securing

- Importance: Properly secured pipes are less likely to vibrate and amplify noise.

- Methods: Use appropriate clamps, brackets, and hangers at recommended intervals.

Slow-Closing Valves

- Advantages: Gradually stopping water flow reduces sudden pressure changes.

- Applications: Consider replacing existing valves with slow-closing models, especially on appliances.

Selecting the Right Water Hammer Arrestor

Assessing System Requirements

- Flow Rate and Pressure: Measure your system’s operating conditions.

- Fixture Types: Identify fixtures that contribute to water hammer due to rapid closing.

Consulting Manufacturers’ Guidelines

- Use sizing charts and technical support provided by manufacturers like Lehry Valves to select the appropriate arrestor.

Budget Considerations

- Cost vs. Benefit: While arrestors represent an upfront investment, they can prevent costly repairs in the long run.

- Quality and Warranty: Opt for reputable brands that offer warranties and proven reliability.

Benefits of Addressing Water Hammer

Protecting Plumbing Infrastructure

- Preventing Damage: Avoid potential disasters like burst pipes and flooding.

- Extending Lifespan: Reduce wear on pipes and appliances, prolonging their usefulness.

Enhancing Comfort

- Noise Reduction: Enjoy a quieter home without disruptive banging sounds.

- Improving System Performance: Experience consistent water flow and pressure.

Energy and Cost Savings

- Efficiency: A well-maintained system operates more efficiently, possibly reducing utility bills.

- Avoiding Emergency Repairs: Proactive measures save money by preventing unexpected breakdowns.

Frequently Asked Questions (FAQs)

1. Do I need a water hammer arrestor in my home?

If you hear banging noises when shutting off water fixtures or notice vibrations in your pipes, a water hammer arrestor can help eliminate these issues and protect your plumbing system.

2. Can I install a water hammer arrestor myself?

While it’s possible for individuals with plumbing experience to install an arrestor, hiring a licensed plumber ensures proper installation, compliance with local codes, and optimal performance.

3. How long do water hammer arrestors last?

The lifespan varies depending on the type and usage. High-quality mechanical arrestors can last many years, but regular inspections are recommended to ensure ongoing effectiveness.

4. Are water hammer arrestors required by code?

Some local plumbing codes require the installation of water hammer arrestors in certain situations. It’s important to check with your local building authority to determine specific requirements.

5. Will a water hammer arrestor reduce my water pressure?

No, water hammer arrestors are designed to absorb shock waves without affecting the normal water pressure or flow in your system.

Conclusion

Water hammer is more than just a noisy nuisance; it can lead to significant damage and costly repairs if left unaddressed. Installing a water hammer arrestor is a practical and effective solution to protect your plumbing system, enhance comfort, and ensure the longevity of your home’s infrastructure.

By understanding the causes and effects of water hammer, you can take proactive steps to mitigate its impact. Whether you’re a homeowner dealing with banging pipes or a building manager seeking to maintain system integrity, addressing water hammer is a wise investment in safety and peace of mind.

Additional Resources

- Related Articles:

- “Preventing Plumbing Disasters: A Homeowner’s Guide”

- “Understanding Your Home’s Water Pressure System”

- References:

- Lehry Valves – Water Hammer Arrestor

- Plumbing code references and standards (e.g., ASSE Standard 1010)

- Manufacturer technical guides and sizing charts

By taking the time to assess your plumbing needs and consult with professionals, you can effectively eliminate water hammer from your system. Investing in a quality water hammer arrestor not only protects your property but also provides a more comfortable living environment.