Pipes and Pipe Fttings

- Home

- Pipes and Pipe Fttings

Pipes & Pipe Fittings

Global Reach with Local Understanding

Lead-free UPVC (Unplasticized Polyvinyl Chloride) pipes and fittings offer a safe and reliable solution for potable water distribution systems. These pipes are specifically designed to meet stringent standards for drinking water applications, ensuring the highest levels of health and safety for consumers. Unlike traditional PVC pipes, UPVC pipes are manufactured without the addition of lead, making them non-toxic and environmentally friendly.

The inherent properties of UPVC, such as corrosion resistance, durability, and smooth interior surface, make it an ideal choice for potable water distribution. These pipes are resistant to chemical reactions and external environmental factors, ensuring long-term performance and minimal maintenance requirements. Additionally, UPVC pipes exhibit excellent hydraulic properties, providing efficient water flow and distribution throughout the system.

Furthermore, UPVC fittings are precision-engineered to ensure leak-proof connections and compatibility with UPVC pipes. They are easy to install, allowing for quick and hassle-free assembly, reducing installation time and costs. With their proven track record of reliability and safety, lead-free UPVC pipes and fittings are the preferred choice for residential, commercial, and municipal water distribution systems, providing peace of mind to consumers and stakeholders alike.

Leak-proof sewage systems are essential for maintaining sanitation and preventing environmental contamination in urban and industrial environments. These systems are designed to effectively convey and manage sewage waste while minimizing the risk of leaks and spills.

Utilizing advanced materials and construction techniques, leak-proof sewage systems incorporate features such as seamless joints, corrosion-resistant components, and robust seals to ensure watertight integrity throughout the entire network. High-density polyethylene (HDPE) pipes are often used for their durability, flexibility, and resistance to chemical and biological degradation, making them an ideal choice for sewage conveyance.

In addition to the pipes themselves, leak-proof sewage systems also include specialized fittings, manholes, and inspection chambers engineered to withstand the harsh conditions of sewage environments. These components are designed to provide secure connections and easy access for maintenance and inspection purposes.

By preventing leaks and spills, leak-proof sewage systems help to safeguard public health, protect natural ecosystems, and minimize the risk of costly environmental remediation efforts. With their reliability, durability, and environmental benefits, these systems play a crucial role in ensuring sustainable and efficient sewage management for communities and industries alike.

Lightweight manhole and chamber covers offer a practical and efficient solution for access points in sewerage, drainage, and utility systems. These covers are specifically designed to provide secure and easy access to underground infrastructure while minimizing the weight and physical burden associated with traditional heavy-duty covers.

Constructed from durable yet lightweight materials such as high-density polyethylene (HDPE) or composite materials, these covers maintain the necessary strength and load-bearing capacity while significantly reducing their overall weight. This lightweight design facilitates easier handling during installation, maintenance, and inspection tasks, reducing the risk of workplace injuries and streamlining operational processes.

Despite their lightweight construction, these covers are engineered to withstand heavy loads and harsh environmental conditions, ensuring long-term durability and performance. They are resistant to corrosion, rust, and degradation from exposure to chemicals, moisture, and UV radiation, providing reliable protection for underground infrastructure in various applications.

Furthermore, lightweight manhole and chamber covers often feature ergonomic designs and innovative features such as anti-slip surfaces, locking mechanisms, and customization options to meet specific project requirements. These features enhance safety, security, and functionality while providing convenient access for authorized personnel.

Overall, lightweight manhole and chamber covers offer a practical and cost-effective solution for municipalities, utilities, and construction projects seeking to optimize operational efficiency, reduce maintenance costs, and improve safety in underground infrastructure management.

High-quality water storage tanks are essential components of water supply systems, providing reliable storage capacity for potable water in residential, commercial, industrial, and agricultural settings. These tanks are designed to withstand the rigors of long-term water storage while ensuring water quality, safety, and accessibility for various applications.

Constructed from durable materials such as high-density polyethylene (HDPE), fiberglass, or stainless steel, high-quality water storage tanks offer exceptional strength, corrosion resistance, and longevity. These materials are engineered to withstand harsh environmental conditions, UV exposure, and chemical degradation, ensuring the integrity and purity of stored water over time.

Moreover, high-quality water storage tanks feature innovative design elements such as reinforced walls, seamless construction, and FDA-approved liners to prevent leaks, contamination, and bacterial growth. They are equipped with secure fittings, valves, and access points for easy filling, monitoring, and distribution of water as needed.

Additionally, these tanks may incorporate advanced features such as insulation, UV protection, and overflow prevention mechanisms to enhance performance and efficiency in various climates and applications. They are available in a range of sizes, shapes, and configurations to accommodate specific storage requirements and space constraints.

Whether used for residential rainwater harvesting, agricultural irrigation, emergency water supply, or industrial process water storage, high-quality water storage tanks provide a dependable and sustainable solution for managing water resources. With their robust construction, reliable performance, and compliance with regulatory standards, these tanks contribute to water security, resilience, and sustainability in communities worldwide.

Durable cable ducting pipes are essential components of underground utility infrastructure, providing reliable protection and management for electrical cables in various applications such as telecommunications, power distribution, and data transmission. These pipes are specifically designed to withstand the challenges of underground environments while ensuring the safety, integrity, and accessibility of cables for installation, maintenance, and repair tasks.

Constructed from durable materials such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), or fiberglass reinforced plastic (FRP), durable cable ducting pipes offer exceptional strength, flexibility, and resistance to environmental factors such as moisture, chemicals, and soil pressure. They are engineered to provide reliable protection against physical damage, abrasion, and impact from external forces, ensuring the long-term integrity and performance of enclosed cables.

Moreover, durable cable ducting pipes feature smooth inner surfaces, seamless construction, and secure fittings to facilitate easy cable installation, minimize friction, and prevent damage to cable insulation during pulling and laying operations. They are available in various diameters, lengths, and configurations to accommodate different cable sizes, installation requirements, and project specifications.

Additionally, these pipes may incorporate advanced features such as UV stabilization, flame retardancy, and anti-static properties to enhance performance and safety in diverse environments and applications. They are designed to meet industry standards and regulatory requirements for electrical installations, ensuring compliance, reliability, and peace of mind for contractors, utilities, and end-users.

Overall, durable cable ducting pipes provide a dependable and cost-effective solution for protecting and managing underground cables, supporting the efficient and reliable operation of electrical infrastructure in urban, industrial, and rural settings. With their robust construction, reliable performance, and longevity, these pipes contribute to the safety, reliability, and sustainability of underground utility networks.

Advanced CPVC (Chlorinated Polyvinyl Chloride) pipes and fittings offer reliable solutions for modern plumbing needs, providing dependable performance and durability in various applications. Engineered with advanced materials and manufacturing techniques, these pipes and fittings are designed to meet the stringent requirements of modern plumbing systems, offering superior resistance to corrosion, chemicals, and high temperatures.

CPVC pipes and fittings are specifically formulated to withstand the demands of hot and cold water distribution systems, making them ideal for residential, commercial, and industrial plumbing applications. Their smooth interior surface ensures optimal flow rates and minimizes friction losses, contributing to efficient water distribution and reduced energy consumption.

Furthermore, CPVC pipes and fittings are lightweight and easy to install, allowing for quick and cost-effective installation in new construction projects or retrofitting existing plumbing systems. Their robust construction and leak-proof joints provide long-term reliability and peace of mind for homeowners, contractors, and building owners.

With their proven track record of performance, durability, and versatility, advanced CPVC pipes and fittings have become the preferred choice for modern plumbing systems, offering reliable solutions to meet the evolving needs of today's construction industry.

SWR (Soil, Waste, and Rainwater) pipes and fittings offer robust solutions for efficient drainage systems, ensuring the effective conveyance of waste and rainwater from residential, commercial, and industrial buildings. Designed with durability and reliability in mind, SWR pipes and fittings are constructed from high-quality materials such as uPVC (unplasticized Polyvinyl Chloride) or PVC, which provide excellent resistance to corrosion, chemical degradation, and environmental factors.

These pipes and fittings are engineered to withstand the challenges of drainage applications, including exposure to moisture, soil pressure, and fluctuating temperatures. Their seamless construction and secure joints minimize the risk of leaks, blockages, and structural failures, ensuring long-term performance and minimal maintenance requirements.

SWR pipes and fittings are available in a variety of sizes, configurations, and specifications to accommodate different drainage requirements and building codes. Whether used for soil drainage, waste disposal, or rainwater harvesting, these components are designed to optimize flow rates, prevent backups, and maintain hygienic conditions within buildings.

Furthermore, SWR pipes and fittings are easy to install and maintain, offering contractors and building owners a cost-effective and efficient solution for drainage system installations and upgrades. With their proven durability, reliability, and efficiency, SWR pipes and fittings are the preferred choice for architects, engineers, and construction professionals seeking robust solutions for efficient drainage systems.

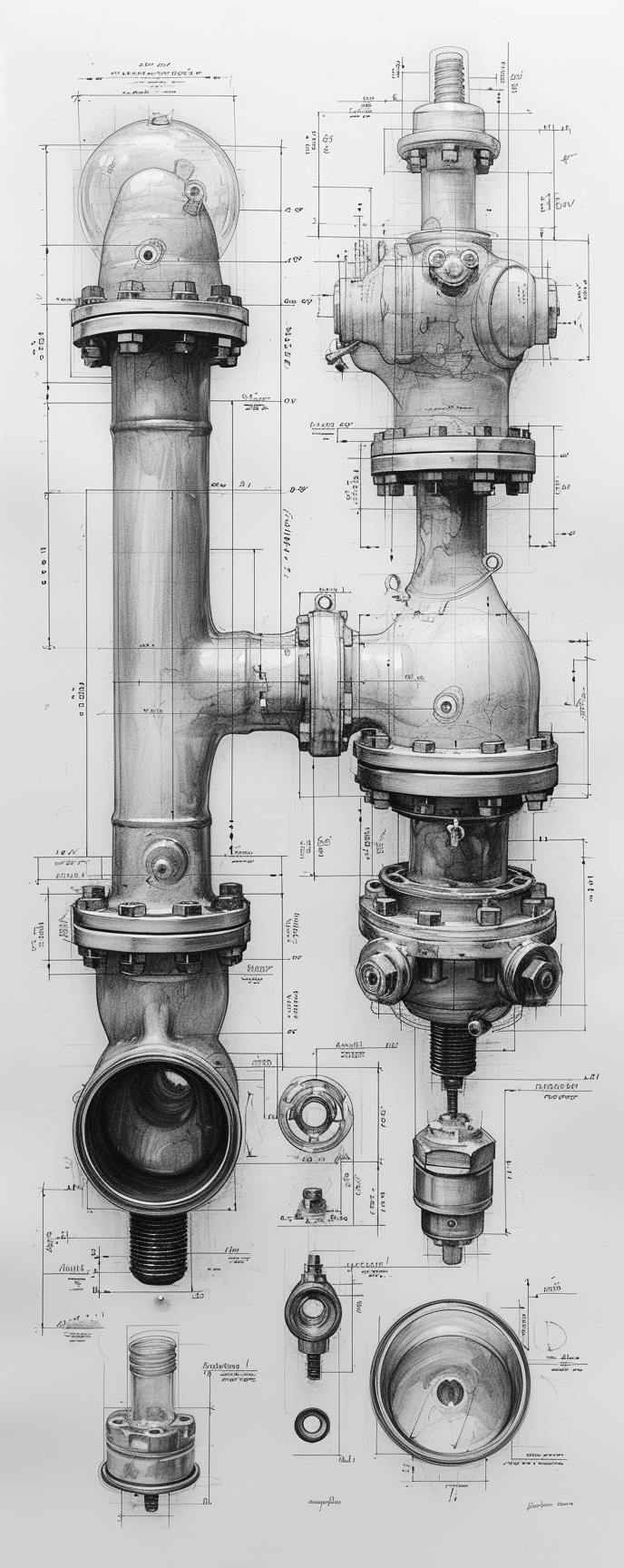

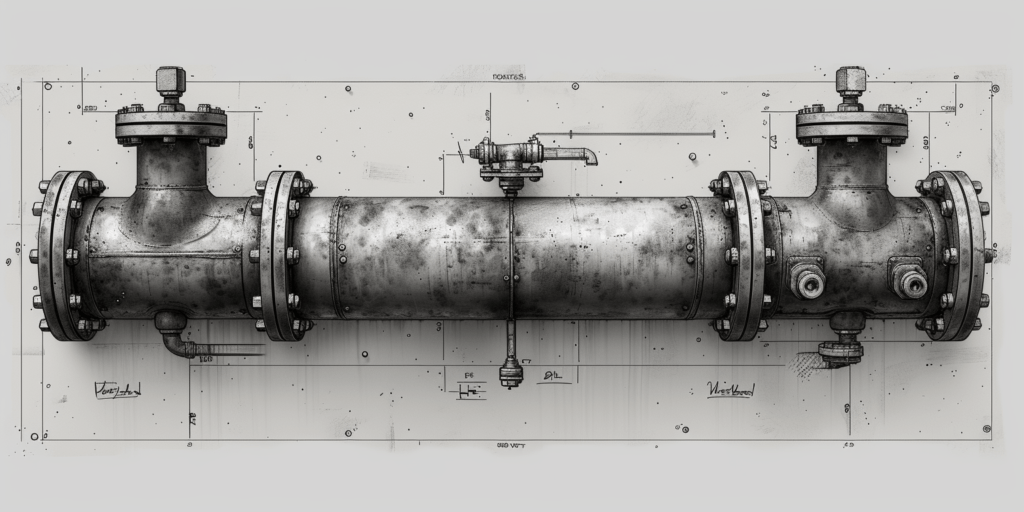

Cast iron pipe fittings offer durable solutions for a wide range of industrial and municipal applications, providing reliable conveyance of water, wastewater, and other fluids. Known for their exceptional strength, longevity, and resistance to corrosion, cast iron fittings are a preferred choice for demanding environments where durability and performance are paramount.

These fittings are manufactured using high-quality cast iron materials, ensuring robustness and structural integrity under heavy loads and harsh conditions. Their solid construction and precise machining result in tight seals and leak-proof connections, minimizing the risk of fluid leakage and ensuring the integrity of the piping system.

Cast iron pipe fittings are highly versatile and can be used in various applications, including water supply, sewage disposal, stormwater management, and industrial process piping. They are capable of withstanding high pressures, temperature fluctuations, and abrasive materials, making them suitable for both above-ground and underground installations in industrial plants, wastewater treatment facilities, and municipal infrastructure projects.

Furthermore, cast iron fittings require minimal maintenance and offer long-term reliability, reducing lifecycle costs and ensuring uninterrupted operation of critical systems. With their proven durability and performance, cast iron pipe fittings continue to be a preferred choice for industrial and municipal applications where ruggedness and reliability are essential.

Composite pipes offer versatile and durable solutions for a wide range of applications, providing reliable conveyance of fluids in diverse industries such as plumbing, HVAC (heating, ventilation, and air conditioning), chemical processing, and oil and gas. These pipes are engineered using advanced composite materials, typically consisting of a combination of fibers (such as fiberglass or carbon fiber) and a polymer resin matrix (such as epoxy or polyester), resulting in a lightweight yet robust construction.

One of the key advantages of composite pipes is their versatility, as they can be tailored to meet specific application requirements, including high temperature, high pressure, corrosive environments, and underground installations. Additionally, composite pipes are available in various diameters, lengths, and configurations to accommodate different flow rates, operating conditions, and installation constraints.

Composite pipes are known for their exceptional durability and resistance to corrosion, abrasion, and chemical attack, making them suitable for demanding industrial applications where traditional materials may fail prematurely. They offer a long service life with minimal maintenance requirements, reducing downtime and lifecycle costs for end-users.

Furthermore, composite pipes are lightweight and easy to handle, transport, and install, resulting in faster and more cost-effective installations compared to metal or concrete pipes. Their smooth interior surface promotes efficient fluid flow, reducing friction losses and energy consumption over time.

Overall, composite pipes provide versatile and durable solutions for various applications, offering reliability, performance, and longevity in challenging operating environments. With their ability to withstand harsh conditions and deliver consistent performance, composite pipes continue to be a preferred choice for industries seeking efficient and cost-effective fluid conveyance solutions.