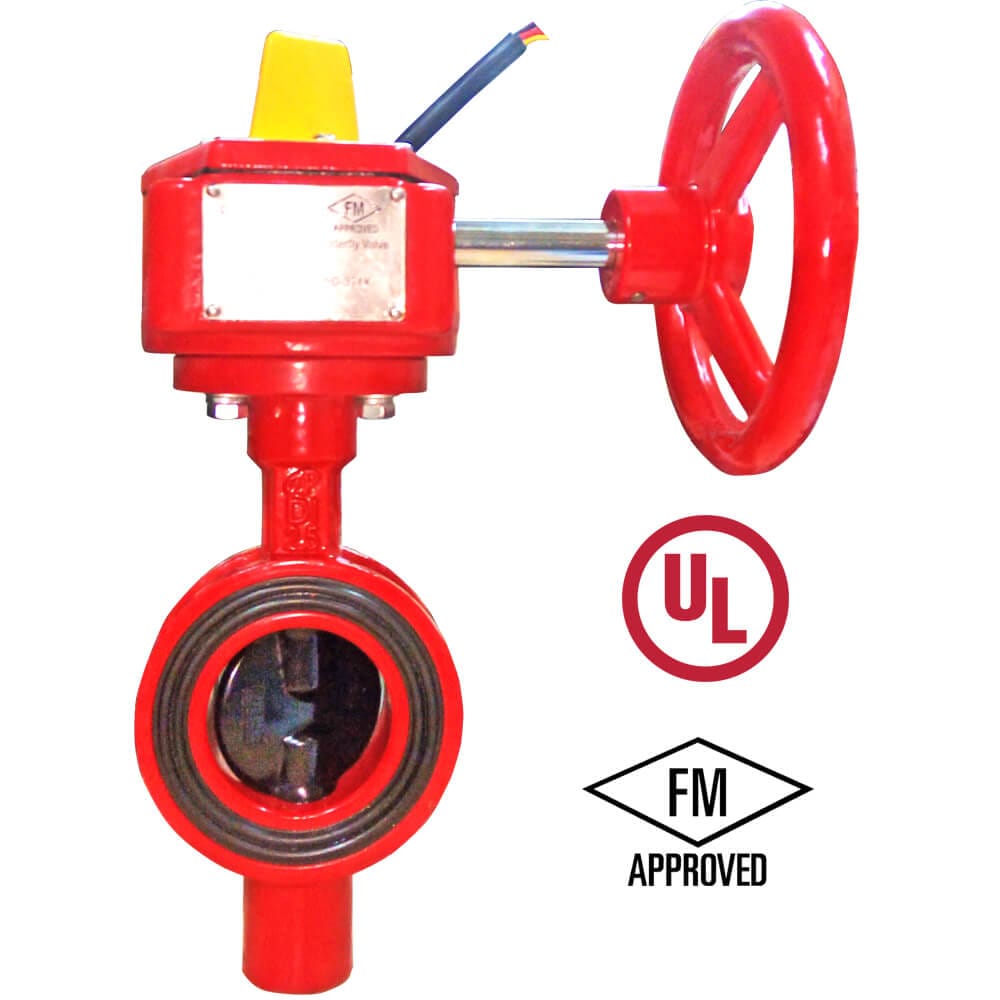

Wafer Type Butterfly Valve

Wafer Type Butterfly Valves: A Comprehensive Overview

Butterfly valves are essential components in fluid control systems, enabling efficient and reliable regulation of fluid flow across various industries. Among the different types of butterfly valves, the wafer type stands out due to its compact design, ease of installation, and cost-effectiveness. This article offers a comprehensive overview of wafer type butterfly valves, delving into their working principles, diverse types and applications, materials used in their construction, advantages and disadvantages, maintenance and troubleshooting procedures, and finally, prominent manufacturers and suppliers in the industry.

Materials of Construction

The selection of materials for wafer type butterfly valves is a critical consideration, as it directly impacts the valve’s performance, durability, and suitability for specific applications. The materials used vary depending on factors such as the nature of the fluid being handled, the operating temperature and pressure, and the required corrosion resistance1. Common materials used in the construction of wafer type butterfly valves include:

- Valve Body: The valve body, which forms the main structure of the valve, is typically made of ductile iron, cast iron, carbon steel, or stainless steel2. Ductile iron offers a good balance of strength and corrosion resistance, while cast iron provides cost-effectiveness for less demanding applications. Carbon steel is often used for higher-pressure applications, and stainless steel provides excellent corrosion resistance for harsh environments.

- Disc: The disc, which acts as the flow control element, is commonly constructed from stainless steel, ductile iron, or aluminum bronze3. Stainless steel discs offer excellent corrosion resistance and durability, while ductile iron provides good strength and wear resistance. Aluminum bronze is often preferred for marine applications due to its high resistance to saltwater corrosion.

- Seat: The seat, which provides the sealing surface for the disc, is typically made of elastomeric materials such as EPDM (ethylene propylene diene monomer), Buna-N (nitrile rubber), or Viton (fluoroelastomer)3. EPDM is a versatile material with good resistance to water and chemicals, while Buna-N offers excellent resistance to oils and fuels. Viton is known for its high-temperature resistance and compatibility with a wide range of chemicals.

- Stem: The stem, which connects the disc to the actuator, is usually made of stainless steel for its strength and corrosion resistance3.

In addition to these common materials, specialized materials like titanium may be used for specific applications, such as seawater environments, where exceptional corrosion resistance is required1.

Types and Applications

Wafer type butterfly valves are available in a variety of configurations, each tailored to specific applications and operating conditions. Some of the common types include:

- Zero Offset: This is the most basic and cost-effective type of wafer butterfly valve. The stem passes through the center of the disc, which is also located in the center of the pipe bore7. Zero offset butterfly valves are suitable for low-pressure applications where tight shut-off is not critical.

- Double Offset: In double offset butterfly valves, the stem is offset from the centerline of the disc and the body seal. This offset design reduces friction between the disc and the seat, minimizing wear and improving sealing performance9. The cam action created by the offset design also helps to lift the seat out of the seal during operation, further reducing friction and wear9. Double offset butterfly valves are suitable for higher-pressure systems and applications requiring tighter shut-off.

- Triple Offset: Triple offset butterfly valves take the offset design a step further by incorporating a third offset in the sealing surface of the seat. This design virtually eliminates sliding contact between the disc and the seat, resulting in exceptional sealing performance and extended service life7. Triple offset butterfly valves are ideal for high-pressure and high-temperature applications where a tight seal and minimal wear are essential.

In addition to these offset designs, wafer type butterfly valves are also available in different body types:

- Lug-style: Lug-style butterfly valves have threaded inserts (lugs) on both sides of the valve body, allowing them to be installed using bolts without nuts9. This design provides a secure connection and allows for easy installation and removal. Lug-style valves are often used in applications where frequent maintenance is required.

- Double flanged: Double flanged butterfly valves have flanges integrated into the valve body, which are bolted directly to the pipeline flanges7. This design provides a rigid and secure connection, making it suitable for high-pressure applications and systems requiring a high degree of leak tightness.

Wafer type butterfly valves find applications in a wide range of industries and settings, including:

- Power Generation: In power plants, wafer type butterfly valves are used in cooling water systems, gas turbines, and other applications to regulate the flow of water, steam, and gases12. Their compact design and quick operation make them suitable for controlling flow in critical power generation processes.

- Wastewater Systems: Wafer type butterfly valves are commonly used in wastewater treatment plants to control the flow of wastewater and sewage12. Their ability to handle slurries and liquids with suspended solids makes them well-suited for this application.

- Petrochemical Processes: In petrochemical plants, wafer type butterfly valves are used to regulate the flow of various fluids and chemicals throughout the refining and processing stages12. Their corrosion resistance and ability to handle high temperatures make them suitable for demanding petrochemical applications.

- HVAC Systems: Wafer type butterfly valves are used in heating, ventilation, and air conditioning (HVAC) systems to control airflow and maintain desired temperature and pressure levels10. Their compact size and ease of installation make them suitable for use in both commercial and residential HVAC systems.

- Residential Applications: In residential settings, wafer type butterfly valves are used in HVAC systems, swimming pools, and hot tubs to regulate water flow and maintain comfortable temperatures10.

- Pharmaceutical, Chemical, and Food Industries: Wafer type butterfly valves are used in these industries to control the flow of products within various processes9. They are often manufactured to cGMP (current good manufacturing practice) guidelines to ensure hygiene and product safety.

- Water and Oil Pipelines: Due to their ability to handle large flows of liquids at relatively low pressures, wafer type butterfly valves are often used in water and oil pipelines13.

- Internal Combustion Engines: Wafer type butterfly valves are used in carburetors and throttle bodies of internal combustion engines to regulate airflow and control engine speed and power13.

Actuation

Wafer type butterfly valves can be actuated using various methods, providing flexibility in operation and control10. Common actuation methods include:

- Manual Actuation: Manual actuation involves using a lever, handwheel, or gear operator to open or close the valve10. This method is simple and cost-effective, suitable for applications where frequent adjustments are not required.

- Electric Actuation: Electric actuators use an electric motor to control the valve’s position10. They offer precise control and can be automated for remote operation or integration with control systems.

- Pneumatic Actuation: Pneumatic actuators use compressed air to operate the valve10. They are often preferred for applications requiring fast response times and high actuation forces.

- Hydraulic Actuation: Hydraulic actuators use hydraulic fluid to control the valve10. They are typically used for large valves or applications requiring high torque.

In addition to these actuation methods, valve positioners can be used to enhance the accuracy and control of wafer type butterfly valves14. Valve positioners are devices that monitor the valve’s position and adjust the actuator to ensure precise positioning. They are particularly useful in applications requiring accurate flow control or where the valve needs to be positioned at specific intermediate points.

Working Principle

Wafer type butterfly valves operate on a simple yet effective principle. The valve consists of a disc positioned in the center of the pipe. A rod passes through the disc and connects to an actuator on the outside of the valve9. Rotating the actuator turns the disc, changing its orientation relative to the flow path.

When the disc is parallel to the flow, the valve is fully open, allowing fluid to pass through with minimal restriction15. Conversely, when the disc is rotated 90 degrees to be perpendicular to the flow, it acts as a barrier, effectively stopping the flow9. This quarter-turn operation allows for quick and easy control of fluid flow16.

Unlike ball valves, where the ball moves out of the flow path when open, the disc in a butterfly valve is always present within the flow. This results in a pressure drop even when the valve is fully open9. However, the streamlined design of wafer type butterfly valves helps to minimize this pressure drop and enhance operational efficiency16.

Advantages and Disadvantages

Wafer type butterfly valves offer several advantages over other valve types, making them a popular choice in various applications:

- Compact Design: Their compact size and lightweight construction make them ideal for installations where space is limited17. This is particularly advantageous in applications with complex piping systems or confined spaces.

- Easy Installation: Wafer type valves are designed for easy installation, requiring less time and effort compared to other valve types11. Their simple design allows them to be easily installed between two pipe flanges without the need for additional components or complex procedures.

- Cost-Effective: Wafer type butterfly valves are generally less expensive than other valve designs, such as ball valves or gate valves13. This cost-effectiveness makes them an attractive option for budget-conscious projects.

- Quick Operation: Their quarter-turn operation allows for quick opening and closing, making them suitable for applications requiring rapid response times13.

- Good Flow Characteristics: Wafer type butterfly valves offer good flow characteristics with minimal pressure drop when fully open19. This makes them suitable for applications where maintaining flow rate is important.

However, wafer type butterfly valves also have some limitations:

- Flow Control: While wafer type butterfly valves can be used for throttling flow, they may not provide the same level of precise flow control as some other valve types, particularly at partial openings20. However, specific valve designs or the use of valve positioners can improve their flow control capabilities.

- Pressure Drop: The pressure drop across wafer type butterfly valves can be higher compared to some other valve types, especially at higher flow rates9. This should be considered when selecting a valve for applications where pressure drop is a critical factor.

- Sealing Limitations: While wafer type butterfly valves provide a good seal for many applications, they may not be suitable for high-pressure or high-temperature applications where absolute leak tightness is required11. In such cases, other valve types, such as lug-style or double flanged butterfly valves, may be more appropriate.

Cost Comparison:

| Valve Type | Relative Cost | Advantages | Disadvantages |

|---|---|---|---|

| Wafer Butterfly Valve | Low | Compact design, easy installation, quick operation | Limited flow control at partial openings, higher pressure drop |

| Ball Valve | Medium | Tight shut-off, good for on/off control | Can be more expensive, larger size |

| Gate Valve | High | Good for isolation, low pressure drop when fully open | Slow operation, not suitable for throttling |

Standards and Certifications

Wafer type butterfly valves are designed and manufactured to meet various industry standards and certifications, ensuring their quality, safety, and performance. Some of the relevant standards include:

- AWWA C504: This standard from the American Water Works Association specifies requirements for butterfly valves used in waterworks applications.

- API 609: This standard from the American Petroleum Institute provides guidelines for butterfly valves used in the petroleum and natural gas industries.

- UNI EN Standards: These European standards define requirements for various aspects of butterfly valves, including materials, testing, and performance4.

- ISO Standards: International Organization for Standardization (ISO) standards provide guidelines for quality management, testing, and other aspects of valve manufacturing21.

Compliance with these standards ensures that wafer type butterfly valves meet specific performance criteria and are suitable for their intended applications.

Maintenance and Troubleshooting

Proper maintenance is essential to ensure the long-term reliability and performance of wafer type butterfly valves. Regular inspection and maintenance can help to prevent problems and extend the valve’s service life. Some essential maintenance practices include:

- Regular Inspection: Periodically inspect the valve for any signs of wear or damage, such as leakage, corrosion, or loose components22. This can be done visually or by performing tests to check for leaks or other issues.

- Cleaning: Regularly clean the valve and surrounding pipework to remove any debris or buildup that could affect performance22. This may involve flushing the valve with water or using appropriate cleaning agents.

- Lubrication: Lubricate the stem and disc to ensure smooth operation and prevent wear22. Use a lubricant that is compatible with the valve’s materials and the fluid being handled.

- Seat Replacement: If the valve seat shows signs of wear or damage, replace it to maintain a tight seal22. Seat replacement is a relatively simple maintenance procedure that can be performed in the field.

Troubleshooting common problems:

- Leakage: Leakage can be caused by various factors, including a worn seat, damaged stem, or foreign material between the seat and disc14. Inspect the valve carefully to identify the source of the leak and take appropriate corrective action.

- Slow Operation: Slow operation or difficulty in changing direction can be due to poor lubrication, a stuck spring, or debris in the valve14. Check the lubrication, inspect the spring, and clean the valve to resolve these issues.

- Actuator Problems: Issues with the actuator, such as a faulty solenoid valve or electrical circuit problems, can affect valve operation14. Troubleshoot the actuator to identify and resolve the problem.

Manufacturers and Suppliers

The market for wafer type butterfly valves is served by numerous manufacturers and suppliers, each offering a range of products with different features and specifications. Some of the leading manufacturers include:

| Manufacturer | Headquarters | Key Products/Specializations | Applications |

|---|---|---|---|

| Butterfly Valves & Controls, Inc. | Grapevine, TX | Butterfly control valves and related components | Various industrial applications |

| Flowserve Corporation | Irving, TX | High-pressure valves, steam valves, stainless steel valves | Power generation, oil and gas, water treatment |

| Jomar Valve | Warren, MI | Brass valves, lead-free valves, stainless and carbon steel valves | Industrial and residential plumbing, utilities, HVAC |

| GF Piping Systems | Irvine, CA | High-performance butterfly valves | Industrial water treatment, chemical processing |

| U.S. Plastic Corp. | Lima, OH | Wafer type butterfly valves | Water and wastewater treatment, power generation, oil and gas |

| Powell Valves | High-performance butterfly valves, resilient seated butterfly valves | Various industrial applications | |

| VALTECCN | Concentric, eccentric, wafer type, lug type, PTFE lined butterfly valves | Natural gas, oil, oil refining, chemical, marine, power generation | |

| Crane Co. | Stamford, CT | Triple offset butterfly valves, high-performance butterfly valves | Various industrial applications |

| DeZurik, Inc. | Sartell, MN | Wafer butterfly valves, flange butterfly valves | Various industrial applications |

| Milwaukee Valve Company | New Berlin, WI | Wafer butterfly valves, flange butterfly valves | Various industrial applications |

In addition to these manufacturers, several distributors and suppliers specialize in providing wafer type butterfly valves and related products. These suppliers often offer a wide selection of valves from different manufacturers, allowing customers to find the best solution for their specific needs.

Technical Specifications and Datasheets

Technical specifications and datasheets provide detailed information about the performance characteristics, dimensions, and materials of wafer type butterfly valves. These documents are essential for engineers and technicians to select the appropriate valve for their application.

Example Specifications:

| Specification | Value | Source |

|---|---|---|

| Pipe Size | 4 inch wafer design | 24 |

| Suitable Flanges | ANSI /ASME B16.5 Class 150, B16.1 Class 125, EN1092 PN10, PN16, BS10 D, E, JIS B2239 10K, 16K | 24 |

| Flow Capacity | Cv 929 (Cv = number of GPM of 60 °F water at 1 psi pressure drop) | 24 |

| Pressure Rating | 29 inHg vacuum to 230 PSI | 24 |

| Temperature Range | 5 to 185 °F (-15 to +85 °C) | 24 |

| Valve Body | Ductile iron, 3-layer Epoxy/Epoxy/PUR coating (seat facing acts as flange gasket) | 24 |

| Disc | 316 stainless steel | 24 |

| Disc Seat/Liner | NBR (Buna-N) | 24 |

| Shaft Seals | NBR (Buna-N) V-ring | 24 |

| Upper/Lower Stem | SS420 | 24 |

| Actuator Mount | ISO5211, F05/07, 14mm square stem | 24 |

| Body | GG25 Cast iron | 25 |

| Max. Working Temperature | 130 ºC | 25 |

| Body type | 567 – Wafer-style housing | 21 |

| Pressure ratings | DN50-300. PN10 | 21 |

| Connections | Flanges. PVC-U, PVC-C, ABS, PP-H, PVDF, PE according to ISO 7005 PN. 10, EN 1092 PN 10, DIN 2501 PN 10, ANSI/ASME B 16.5 Class. 150, BS 1560: 1989, BS 4504, JIS B 2220 | 21 |

| Available in sizes | 2″ to 48″ | 26 |

| Pressure ratings | 2″ to 12″ — 200 psi | 26 |

| Sizes | 2 in. – 12 in. ( DN50 – DN300) | 27 |

| Maximum Working Pressure | 2 in. – 8 in. ( DN50 – DN200) . . . 300 psi (20,7 bar) | 27 |

Datasheets often include detailed drawings with dimensions, material specifications, pressure and temperature ratings, and other relevant information. Consulting datasheets from different manufacturers is crucial for selecting the most suitable wafer type butterfly valve for a specific application.

Comparison with Other Valve Types

While wafer type butterfly valves offer several advantages, it’s essential to compare them with other common valve types to understand their strengths and limitations in different situations.

| Feature | Wafer Butterfly Valve | Ball Valve | Gate Valve | Globe Valve |

|---|---|---|---|---|

| Operation | Quarter-turn | Quarter-turn | Multi-turn | Multi-turn |

| Flow Control | Moderate | Good for on/off control | Poor | Good |

| Pressure Drop | Higher | Lower | Lowest when fully open | Higher |

| Cost | Lower | Medium | Higher | Higher |

| Size and Weight | Compact and lightweight | Larger and heavier | Larger and heavier | Larger and heavier |

| Maintenance | Relatively easy | Can be more complex | Can be more complex | Can be more complex |

| Applications | Water, wastewater, HVAC, general purpose | Isolation, on/off control | Isolation | Throttling, flow control |

Wafer type butterfly valves are generally preferred over ball valves when cost and size are major considerations, and precise flow control is not critical. Compared to gate valves, they offer faster operation and are more suitable for throttling flow, although gate valves provide better isolation and lower pressure drop when fully open. Globe valves offer better flow control than butterfly valves but are typically more expensive and larger.

Selection Criteria

Choosing the right wafer type butterfly valve for a specific application requires careful consideration of several factors:

- Pressure and Temperature Ratings: Ensure that the valve’s pressure and temperature ratings are compatible with the operating conditions of the system.

- Material Compatibility: The valve’s materials must be compatible with the fluid being handled to prevent corrosion or degradation.

- Flow Rate and Pressure Drop: Consider the required flow rate and the acceptable pressure drop across the valve.

- Actuation Method: Choose an actuation method that suits the application’s needs, whether manual, electric, pneumatic, or hydraulic.

- Size and Space Constraints: Select a valve size that is appropriate for the pipeline and consider any space limitations in the installation area.

- Cost: Evaluate the cost of the valve in relation to its performance and features.

- Maintenance Requirements: Consider the valve’s maintenance requirements and accessibility for servicing.

By carefully evaluating these criteria, engineers and technicians can select the most suitable wafer type butterfly valve for their specific needs.

Conclusion

Wafer type butterfly valves are versatile and cost-effective solutions for a wide range of fluid control applications. Their compact design, ease of installation, and quick operation make them a popular choice across various industries, from power generation and wastewater treatment to HVAC systems and residential plumbing.

By understanding the different types of wafer type butterfly valves, their materials of construction, actuation methods, advantages, and limitations, engineers and technicians can make informed decisions when selecting and installing these valves. Proper maintenance and troubleshooting procedures are crucial to ensure the long-term reliability and performance of wafer type butterfly valves, maximizing their service life and minimizing downtime.

As technology advances, we can expect to see further innovations in wafer type butterfly valve design and materials, leading to improved performance, efficiency, and reliability. These advancements will further expand the applications of wafer type butterfly valves in various industries and contribute to more efficient and sustainable fluid control systems.

Works cited

1. Types of Butterfly Valves, accessed February 6, 2025, https://qrcvalves.com/types-of-butterfly-valves/

2. fpm.coperion.com, accessed February 6, 2025, https://fpm.coperion.com/process/butterfly-valve-wafer-type/#:~:text=Ductile%20Iron%20(Rilsan%20coated),Carbon%20Steel

3. Wafer Style Commercial Butterfly Valve Series 2300 – J&S Valve, accessed February 6, 2025, https://www.jandsvalve.com/butterfly-wafer-style-2300-wafer-p-441.html

4. Wafer or butterfly valves: characteristics and materials – Intertubi Spa, accessed February 6, 2025, https://www.intertubi.co.uk/blog-en/Wafer-or-butterfly-valves-characteristics-and-materials-253.html

5. Butterfly Valves | Wafer & Lug Styles – Valworx, accessed February 6, 2025, https://www.valworx.com/category/butterfly

6. Butterfly Valve | Wafer | DI Body – Trupply LLC, accessed February 6, 2025, https://www.trupply.com/products/wafer-butterfly-valves

7. What are The Different Types of Butterfly Valves? – Av-Tek Valves, accessed February 6, 2025, https://avtekvalves.com/what-are-the-different-types-of-butterfly-valves/

8. The Ultimate Guide to Butterfly Valves: Types, Applications, and Benefits, accessed February 6, 2025, https://avtekvalves.com/the-ultimate-guide-to-butterfly-valves-types-applications-and-benefits/

9. Butterfly valve – Wikipedia, accessed February 6, 2025, https://en.wikipedia.org/wiki/Butterfly_valve

10. Butterfly Valve Design Differences | Tameson.com, accessed February 6, 2025, https://tameson.com/pages/butterfly-valve-design-differences

11. Wafer vs. Flanged Butterfly Valves: Comparison and Selection Guide, accessed February 6, 2025, https://www.hawsd.com/news/industry-news/wafer-vs-flanged-butterfly-valves-comparison-and-selection-guide.html

12. What Are Some Innovative Applications for a Wafer Type Butterfly Valve?, accessed February 6, 2025, https://povbutterflyvalve.com/what-are-applications-for-a-wafer-type-butterfly-valve/

13. How does a Butterfly Valve work – Hydraulic Valves – YouTube, accessed February 6, 2025, https://www.youtube.com/watch?v=E4q42JB-OM0

14. Common Faults and Solutions for Wafer Butterfly Valves – Hebei Leading Metals & Piping Industries Co., Ltd., accessed February 6, 2025, https://www.hebeileading.com/common-faults-and-solutions-for-wafer-butterfly-valves.html

15. Butterfly valve working principle, accessed February 6, 2025, https://www.jhyvalve.com/resources/butterfly-valve-introduction-guide.html

16. How Does a Wafer Valve Work? A Technical Guide – Butterfly Valve, accessed February 6, 2025, https://povbutterflyvalve.com/wafer-valve-3/

17. What Are the Benefits of Using Lug or Wafer Butterfly Valve? -, accessed February 6, 2025, https://povbutterflyvalve.com/lug-or-wafer-butterfly-valve/

18. What is a Butterfly Valve? Components, Uses, Types, Advantages – GMS Interneer, accessed February 6, 2025, https://www.gmsthailand.com/blog/what-is-butterfly-valve/

19. Lug vs. a Wafer Butterfly Valve, accessed February 6, 2025, https://www.everlastingvalveusa.com/lug-vs-a-wafer-butterfly-valve/

20. What are the advantages and disadvantages of different types of butterfly valves?, accessed February 6, 2025, http://bcstvalve.com/what-are-the-advantages-and-disadvantages-of-different-types-of-butterfly-valves/

21. Datasheet – Butterfly Valve type 567/578 – GF Piping Systems, accessed February 6, 2025, https://www.gfps.com/content/dam/gfps/com/datasheets/en/gfps-datasheet-567-578-butterfly-valve-en.pdf

22. Butterfly Valve Installation & Maintenance Guide – Process Systems, accessed February 6, 2025, https://www.valvesonline.com.au/references/valve-installation-maintenance/butterfly-valves/

23. Troubleshooting Problems with Your Butterfly Valve Gear Type, accessed February 6, 2025, https://povbutterflyvalve.com/butterfly-valve-gear-type/

24. Direct Mount 4″ Butterfly Valve Wafer NBR – Valworx, accessed February 6, 2025, https://www.valworx.com/product/direct-mount-butterfly-valve-wafer-buna-4

25. BUTTERFLY VALVE/WAFER TYPE – Ayvaz, accessed February 6, 2025, https://ayvaz.com/wp-content/uploads/2023/11/Ayvaz_KV-3_Butterfly_Valve.pdf

26. Resilient Seated Butterfly Valves Now All Ductile Iron Body Standard on Series 200 – Crane Engineering, accessed February 6, 2025, https://www.craneengineering.net/hubfs/Product%20Documents/crane-center-line-resilient-seated-butterfly-valves-datasheet.pdf

27. Model BFV-300 Butterfly Valve Wafer Style – GRINNELL, accessed February 6, 2025, https://www.grinnell.com/downloads/TFP1516_06_2019.pdf